Home > Products > Upper & Lower Two Side Planer Machine

Home > Products > Upper & Lower Two Side Planer MachineFeatures

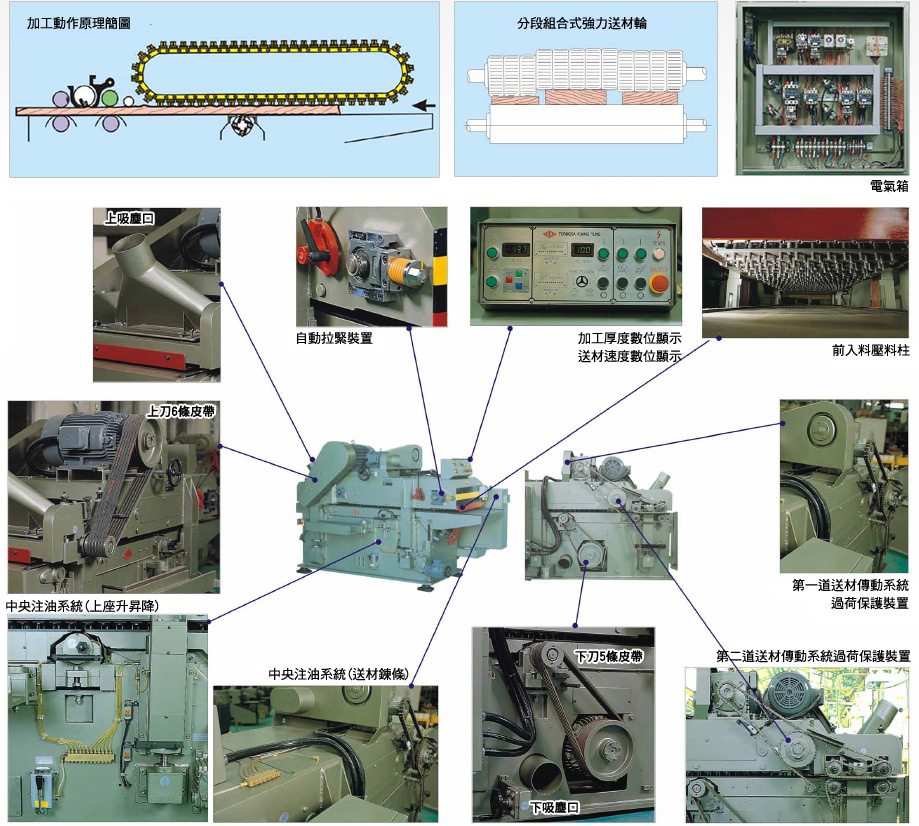

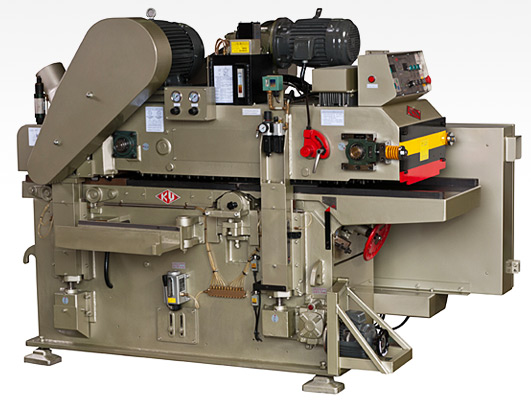

- Multi combination style powerful front press roller and multi combination front wood press plate will get the same surface cutting effect at the same time for the different thickness wood processing.

- The front wood feed in press pin is intersected design, which makes no vacant space and has average pressure on the wood, the narrow wood also can be processed.

- The chain of the upper feeding wood press pin is equipped with auto tighten instrument that makes the chain will always keep tightness no matter how longer or how loosen it is to prevent damaging the machine or unstable operation.

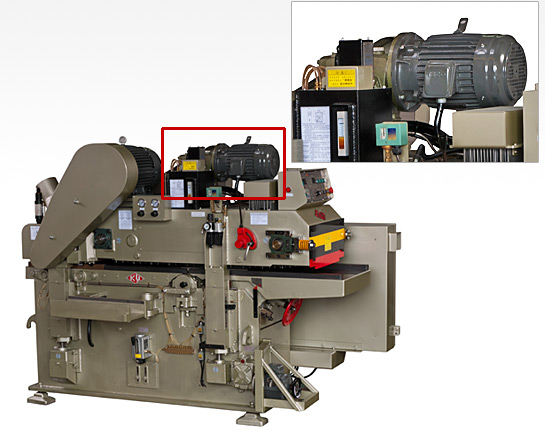

- The motor belt is fixed by the conical collar, to insure the steady operation and will never loosen. The cutter axle belt wheel is fixed by the internal locked thread combine tightly with cutter axle, it will transfer power completely. The 5 belt for 15HP lower cutter and 6 belt for 20HP upper cutter can transfer all the motor power to the cutter axle completely.

- Digital display of the thickness processing is easier to control the size changing.

- Digital display of the feeding speed is easier to manage by eye vision.

- The streamline designed upper and lower dust extraction makes no block when mass process.

- Two sets feeding drive system overload protect device to insure the machine without damage.

- The cutter axle is adopted Europe SKF bearing, high quality and steady.

- The cutter axle is all through the serious heat-treating, it will not damage even the heavy load.

- Enclosed multi cutter correction tools for cutter changing, it can fulfill various necessities.

- The electrical elements and related parts are adopted high class and steady quality to install Electrical devices by company according to decades of experiences. Insure smooth operation and low breakdown rate.

- The electrical device instrument of the upper machine stand lifting is divided into two sets of overload protect switch for raising and descending to insure break power while blocking or wood squeezing when descending the machine stand.

- All the elements and parts of the machine are recorded clearly while producing the machine to ensure the fast and correct supplement service and maintenance service.

Optional Equipment

| PRODUCT | EXPLANATION |

|---|---|

| Feeding speed control by frequency converter (standard) |

|

| Spiral cutter (suggest option) | Include the cutter transport carriage |

KPW-610B-SV / KPW-610A-SV

KPW-610B-SV / KPW-610A-SV Specification

| MODEL | KPW-610B-SV | KPW-610A-SV | |

|---|---|---|---|

| Max. working thickness | 12-120mm | ||

| Max. working width | 605mm | ||

| Min. working length | 350mm | ||

| Revolution of cutter arbor | 4000 rpm/50Hz, 4800rpm/60Hz | ||

| Feeding speed | 2 – 18 m/min | ||

| Power Requirement | Upper arbor motor | 15 HP | 20 HP |

| Lower arbor motor | 15 HP | ||

| Feeding motor | 3HP (feeding speed is controlled by frequency converter) | ||

| Lifting motor | 1/2 HP | ||

| Machine dimension | L2600xW1450 xH1600mm | ||

| Machine weight | 3200Kg | 3250Kg | |